Recently in Motors / Engines Category

My latest acquisition is a beautiful old Garelli moped. I'm still ambivalent as to whether this will be EV converted. For now, here are some pics from the seller.

The seller called it a 1972 Garelli Bonanza, but I'm pretty sure it's a 1976 Garelli Eureka Flex instead. Here are some links to other Garelli Eurekas:

- http://www.mopedarmy.com/photos/brand/18/1844/

- http://www.flickr.com/photos/63216488@N00/3404162837/

MopedArmy.org has the Clymer's repair manual for the Garelli on their website, but it's individual JPG files and I found it difficult to use so I collated them into a single PDF:

I'm working on a bicycle assist motor project. I thought about using a hub motor or chain drive but given the economy, I'm going with a friction drive. Friction drive is cheap, has few little moving parts to go wrong, and is cheap. I think I can make it using parts almost entirely found around the shop -- with the exception of the friction roller.

Now what I like about friction drive is if you use a roller with a one-way bearing and take advantage of some physics, the motor can release from the wheel entirely when freewheeling, so the bicycle remains entirely pedal-able on its own.

I decided to go with rollers from the defunct EV Warrior project. They're available on the surplus market, have one way bearings, and are nicely knurled. Other people are making their own friction rollers from BMX wheel hub extensions, but they don't have one-way bearings.

Here are some dimensions almost entirely for my own benefit.

| Part | Inch | mm |

|---|---|---|

| Shaft OD | 0.500" | 12.70mm |

| Shaft ID | 0.315" (a tad over 5/16") | 8.00 |

| Shaft Width | 3.016" | 76.61 |

| Roller Width | 2.375" 2 3/8" | 60.35 |

| Roller OD | 1.275" ~1 1/4" | 32.38 |

| Key Notch Width | 0.130" | 3.32 |

| Key Notch Depth | 0.411" | 10.4 |

I have the Prius NiMH batteries installed and test drove it but the snowstorm of 2009 has put the dampers on harder testing. In any case, here's the new revised bill of materials (BOM) (dated 2009.12):

| Base Unit |

Piaggio Boxer (1971)

- 50 cc 2-stroke internal combustion engine (removed) |

|---|---|

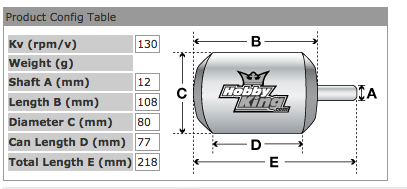

| Electric Motor | HXT 80-100-B 130Kv Brushless Outrunner from HobbyKing

- link to new version of motor - Tachs: 5600 rpm @ 43.2v nominal (4500 rpm @ 36v; 6000 rpm @ 48v) - Max amps drawn: 100A @ 43V - Max watts drawn: ~ 4300 watts - Speed: 45 kph top speed (at current gearing) |

| Electronic Speed Controller |

Castle Creations Phoenix HV-110 (link)

- 110 amps @ 50 volts limit |

| Throttle | Magura 0-5K Potentiometer motorcycle twist grip throttle |

| Servo Tester (Pot to ESC) | Boman Industries Polar-Matic PC-50 (ebay) |

| Power Monitor | Cycle Analyst (link) |

| Batteries | Currently SLA: Prius Gen 2 NiMH

- 6S2P packs (12 in total) - 43.2 volts nominal @ 13 Ah - 330 watt-hours (conservative) - Range: unknown |

| Power Connectors | - Anderson PowerPole 75A on main connections - link

- Anderson PowerPole 30A on sub connections - link |

| Wiring |

- 8 gauge stranded copper on main power lines and motor leads

- 12 gauge stranded copper on sub power lines |

| Lighting | - Front lighting using high-power Luxeon LED

- Rear lighting using high-power red LEDs |

| Low Voltage (12/5VDC) Converters |

|

| Things I burned out/destroyed |

|

When I first started building my Boxer-EV, the motor I installed in it was the largest brushless motor available for RC systems:

Model: HXT80-100-B Wire Turns: 8 Resistance: 32ohm Idle Current: 2A ESC Required: 130A Input Voltage : max. 48V Kv : 130 rpm/V Weight: 1570g Shaft: 12mm Voltage Range: 20-48v Non Load Current: 2.0A Maximum Power: 6500W Equivalent: 60-80cc Gas Engine

I've been very happy with it. With my 48 volt setup, I'm producing enough power that my drive belt started slipping -- so I reduced the gearing a bit to back off the torque. Still, vroom vroom.

ProgressiveRC.com has a great online list of RC brushless motors and you can sort by watts consumed. Looks like there are some great 10,000 watt motors (holy cowabunga!) the only problem being they are around US$2000 and above. My $130 + shipping RC motor is still on the top of the price/performance curve.

It looks like the dealer in Hong Kong I get things from has come out with a new version of the motor. The specs seem the same but they note: "Tight, thick copper windings and 48SH magnets make this motor a real powerhouse. The v2 motor also has screwed end-caps due to the amount of torque this motor produces!"

Model: TR80-100-B Wire Turns: 8 Resistance: 32ohm Idle Current: 2A ESC Required: 130A Input Voltage : max. 48V Kv : 130 rpm/V Weight: 1570g Shaft: 12mm Voltage Range: 20-48v Non Load Current: 2.0A Maximum Power: 6500W Equivalent: 60-80cc Gas Engine

Revised bill of materials (BOM) (dated 2009.09):

[moved to after the jump]

My Piaggio hit the dust a few weeks ago. I went to school with no problems and was on my way back when I heard a loud pop, lost power, and an acrid smoke started pouring out of the ESC/electronics components.

I finally got around to taking the electronics out this weekend. It looked like the Phoenix HV-110A hit the dust.

I was using 2S Pb (SLA) and my max watts were under 100A the entire time (according to my wattmeter). The HV-110 burst into flames when the moped was being driven under relatively light load. This is despite it being force cooled and the ambient temp here relatively cool. Also, the system was under a 90A circuit breaker which didn't trip.

I've contacted Castle Creations and hopefully they'll let me know what happened in more detail and perhaps help me towards a (beefier?) replacement.

Mike A. also asked where I got the 12mm flanged bearing that supports the right side of my outrunner motor. I got it from Carr-McMaster, part #1434K15:

LineMcMasterPart NumberDescription/Customer ID#YouOrderedWeShippedBalanceDueUnitPriceExtendedAmount 1 1434K15 STEEL FLANGE-MOUNTED NEEDLE-ROLLER BEARING, FOR 12MM SHAFT DIAMETER, 60MM OVERALL LENGTH 2EA 2 0 10.26EA 20.52

Pics and specs after jump.

On Sunday, I finished making the bearing mount on the right side of the motor spindle. This will help take a lot of strain off the bearings on the motor and prevent it twisting out from the torque. Also, I shimmed the front pulley with the thin metal from an aluminium can -- it was just perfect to close the gap between 12.5 mm and 12.0 mm. As a result, the motor is working much quieter now -- I just love the sound it makes when it accelerates -- gotta post a video.

(And yes, it's made of wood, I'm a woodworker not a metalworker and don't have access to a mill. The 12mm flanged bearing itself is hidden underneath the wood, it has quality roller bearings to support the spindle.).

I got a new V-belt at the local autoparts store to try to make the gearing taller by forcing the rear CVT smaller, but the V-belt was too small. I'll have to split the difference and get a new V-belt later this week.

Instead of depending on my unreliable low-voltage system for fan power (not good that it cuts out at full throttle), I instead wired two of the fans in serial. That means each fan is being driven by 19 volts -- a bit fast but not something they can't handle. One fan is on the ESC controller, the other I mounted in front of the motor. Unfortunately I found out that the mount I used blocked some of the natural airflow, so the motor ended up running hotter with the fan than it did "naked." I'll have to make another mount that diverts more natural and blown air to the motor.

I've ordered more batteries for the scoot, so now I just have to wait.

Recent Comments